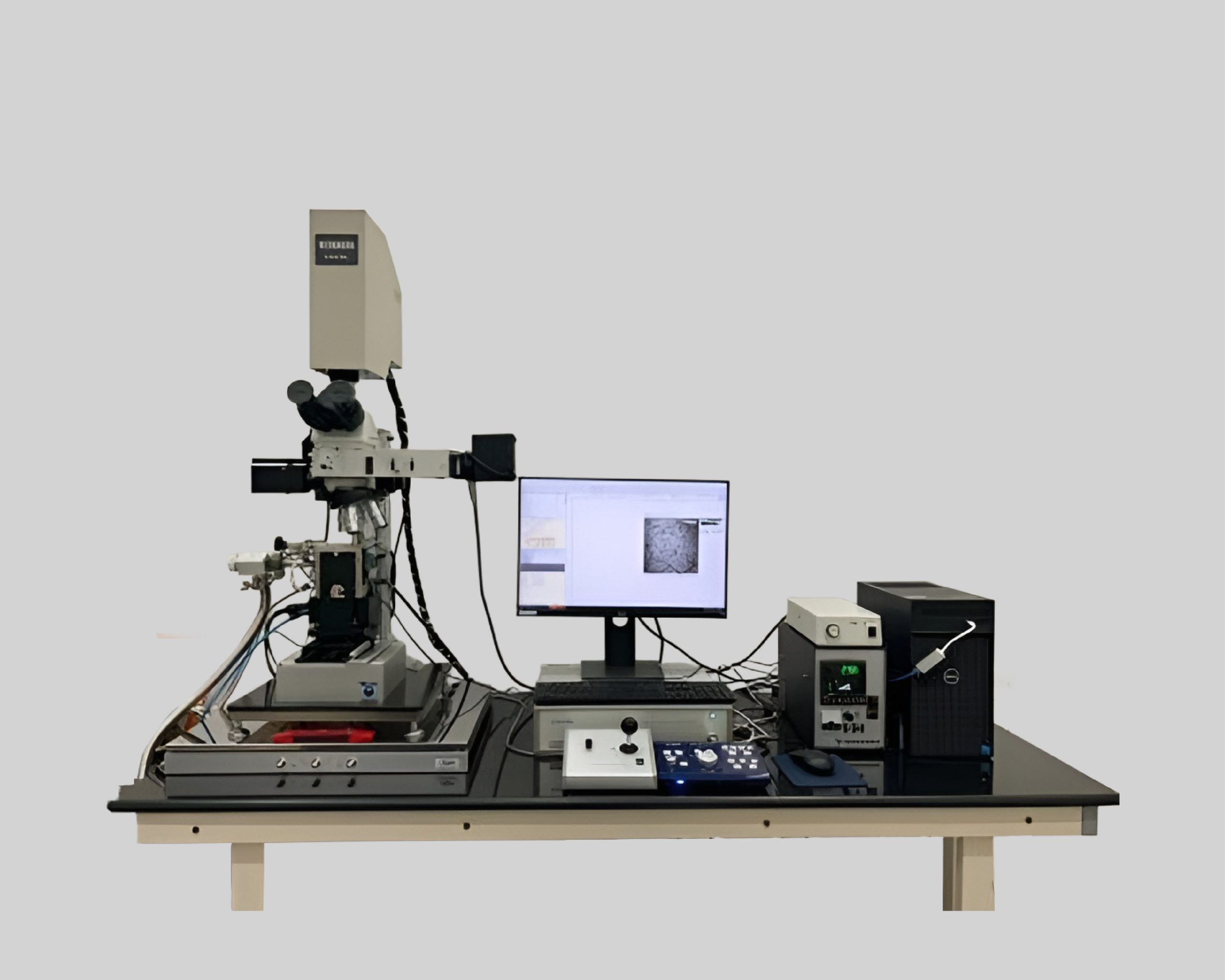

Understanding how materials evolve at high temperatures is critical for designing next-generation metals, ceramics, and functional materials. The High-Temperature Confocal Scanning Laser Microscope (HT-CSLM) enables real-time, in situ visualization of microstructural evolution under controlled thermal and atmospheric conditions, thereby bridging the gap between theory, simulation, and real processing environments. Unlike conventional post-mortem techniques, HT-CSLM captures dynamic phenomena as they happen, delivering unmatched insight into phase transformations, grain evolution, melting, solidification, and interfacial reactions.

Key Application Areas

Metals & Alloys

HT-CSLM is a powerful tool for metallurgical research and process optimization, enabling detailed analysis of the solidification and melting behavior of steels and alloys, as well as inclusion behavior at liquid metal–gas and solid–liquid interfaces. It allows in-situ observation of inclusion agglomeration, flotation, and dissolution, and facilitates studies of recrystallization and grain growth during annealing. Additionally, it provides insights into grain boundary migration and thermal grooving, as well as phase transformations under controlled heating and cooling cycles. Its applications span steelmaking, alloy development, casting, welding, additive manufacturing, and heat-treatment optimization.

Heat Treatment & Process Kinetics

HT-CSLM enables direct visualization of microstructural kinetics, allowing for the observation of how cooling rates influence phase morphology such as pearlite lamellar spacing, the study of transformation temperatures and mechanisms, and the optimization of industrial heat-treatment schedules. It also facilitates the validation of thermodynamic and kinetic models. This capability makes HT-CSLM invaluable for both research and development laboratories as well as industrial process development.

Tool Steels & Carbide Engineering

For advanced steels and ESR-processed alloys, the process involves in-situ melting and dissolution of carbides, followed by observation of carbide precipitation during heating and cooling. The cooling rate has a significant influence on carbide size, distribution, and volume fraction, and a correlation exists between carbide behavior and mechanical performance.

Thin Films & Functional Coatings

HT-CSLM offers unique insights into the stability of thin films at elevated temperatures. It enables the examination of thermal stability and hydrophobic behavior in metallic thin films, while also observing hole formation, ligament breakup, and island formation. Additionally, it enables real-time monitoring of surface morphology evolution during annealing. The technology finds applications in microelectronics, energy devices, catalysts, and protective coatings.

Ceramics & Refractories

For high-temperature ceramic systems, research focuses on grain growth and phase evolution in refractories, the dissolution behavior of spinels and secondary phases, and the study of reaction kinetics at extreme temperatures, reaching approximately 1600 °C. Additionally, it provides insights into degradation mechanisms in metallurgical refractories. This work supports the development of materials for industries such as steel, non-ferrous metals, glass, and energy.

HT-CSLM offers real-time, in-situ observation at high temperatures with controlled inert atmospheres, providing high spatial and temporal resolution. It enables direct correlation between processing conditions and microstructure, making it ideal for academic research, industrial R&D, and model validation. From fundamental studies to industrial applications, it allows live monitoring of material evolution. For more information, please contact us via email sales@antsglobal.in.