India’s transition to electric mobility and renewable energy hinges on cathode active materials (CAM), the backbone of lithium-ion batteries. CAM accounts for 40–50% of battery cost, making it a critical component for performance, safety, and affordability. As EV adoption accelerates, India faces an urgent need to localize the production of cathode materials to reduce import dependence and strengthen its supply chains.

Industry leaders emphasize this priority: “India will require at least 150,000 tonnes of cathode material annually by 2030. Building a strong domestic supply chain is essential for sustainability and cost competitiveness.”: Ankit Sharma, Vidyuta Materials

The Production-Linked Incentive (PLI) scheme empowers India’s manufacturing transformation by offering performance-based rewards to companies for achieving incremental sales and investments, specifically across 14 strategic sectors, including batteries, electronics, pharmaceuticals, and specialty steel.

Key Roles of Heat Treatment in CAM Production

The production of cathode active materials (CAM) involves multiple stages where thermal processing is the key enabler for achieving the desired electrochemical performance. Heat treatment is the backbone of the entire manufacturing line as it defines the crystal structure, phase purity, and particle morphology that directly impact battery capacity, cycle life, and safety.

- Calcination of Precursors, such as hydroxides or carbonates, is converted into stable oxide phases through controlled calcination at high temperatures (typically 700–1000°C). This step ensures proper phase formation and removes residual moisture or volatile compounds.

- Phase Stabilization & Doping: Multi-element cathode materials (e.g., NMC, LFP) require precise thermal profiles to stabilize crystal lattices and incorporate dopants uniformly. Incorrect heating can lead to unwanted phases or structural defects.

- Controlled Atmosphere Processing: Heat treatment under specific atmospheres (oxygen-rich, inert, or vacuum) is crucial for maintaining oxidation states and preventing contamination. For example, oxygen control is critical for NMC cathodes to avoid oxygen vacancies.

- Particle Size & Morphology Control: Thermal conditions influence grain growth and surface characteristics, which in turn affect lithium-ion diffusion and the overall battery performance.

- Coating & Surface Modification: Post-calcination heat treatment facilitates the application of protective coatings (e.g., carbon or oxide layers) to enhance stability and mitigate electrolyte decomposition.

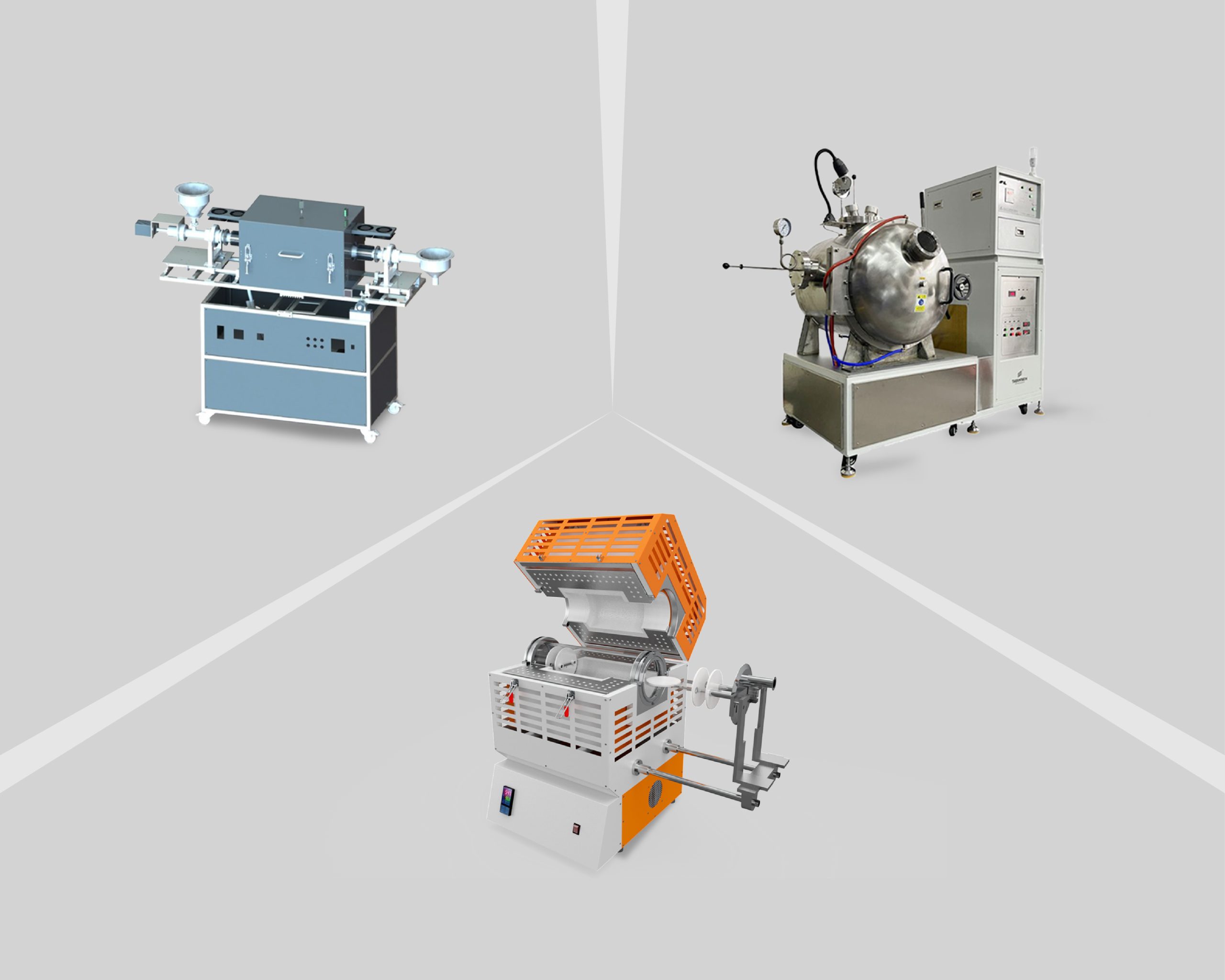

Ants Innovations’ Furnace technologies, offering precise thermal control, are central to cathode material production. Split and multi-zone tube furnaces handle calcination and phase stabilization under controlled atmospheres, ensuring uniform crystal structures and dopant distribution. Rotary tube furnaces enable continuous large-scale powder processing with consistent heating and mixing. Rapid thermal annealing furnaces improve surface coatings and microstructure, while vacuum induction melting furnaces produce high-purity blends and pre-lithiation under inert conditions. These systems ensure repeatable performance, scalability, and quality, which are essential for India’s expanding cathode industry.