Nanomaterials, defined by their structural features within the range of 1–100 nm, are revolutionizing modern science and technology at a higher phase. Their unique properties, such as enhanced surface area, quantum confinement effects, and tunable optical behavior, make them indispensable in fields ranging from energy harvesting and catalysis to biomedical imaging and optoelectronics.

The synthesis of nanomaterials can be said to be an art by materials scientists. Precise control over parameters like temperature, pressure, and chemical environment is essential to tailor their morphology, composition, and surface chemistry. Two primary strategies dominate the field: the top-down approach, which reduces bulk materials to the nanoscale, and the bottom-up approach, which builds nanostructures atom-by-atom or molecule-by-molecule. Among bottom-up techniques, hydrothermal and solvothermal synthesis stand out for their versatility, scalability, and ability to produce high-purity nanomaterials with controlled features.

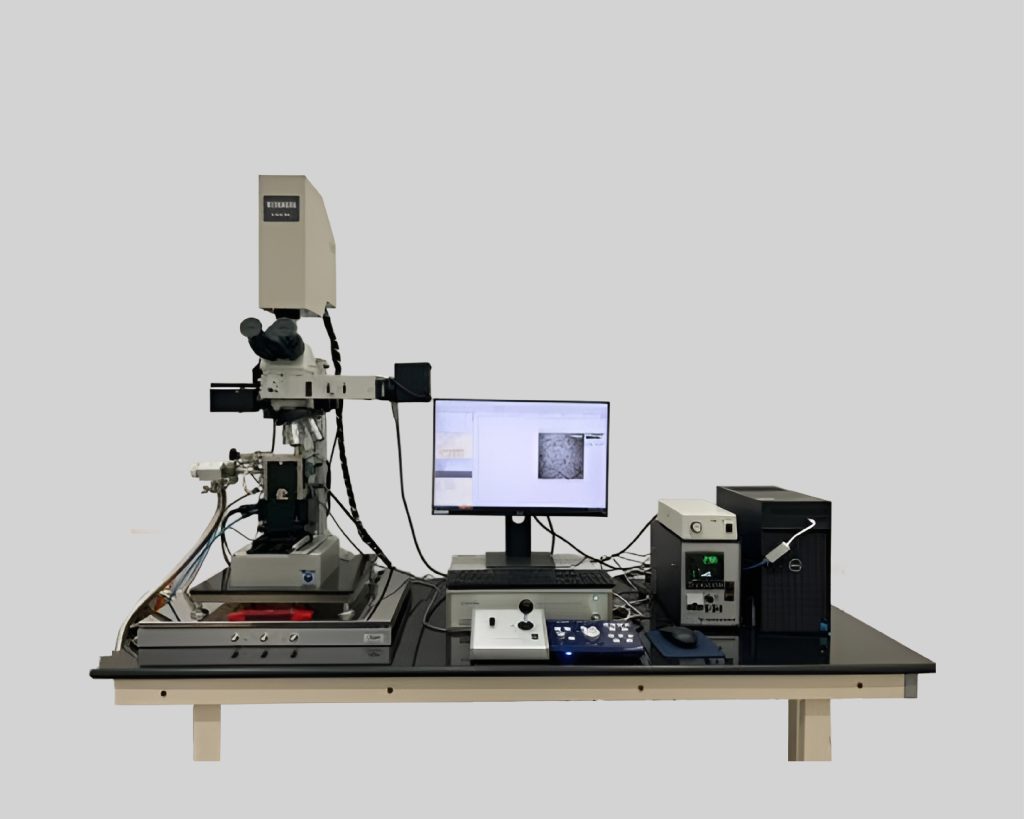

Autoclave: Closed Chamber for Nanomaterial Innovation

Autoclaves are sealed, high-pressure reaction vessels generally made with high strength stainless steel material that enable chemical reactions under superheated conditions with longer life. In hydrothermal synthesis, water serves as the solvent, while solvothermal methods use organic solvents like ethanol or ethylene glycol. These reactions typically occur at temperatures between 100 and 100–220°C and pressures up to 3 MPa, conditions that are only achievable and safely maintained within an autoclave.

A stable environment for the regulated nucleation and growth of nanomaterials is created by the autoclave’s capacity to maintain high pressure, which guarantees that solvents stay in the liquid phase even above their boiling temperatures. The consistency of the reaction and the quality of the final product are further improved by a uniform temperature distribution throughout the vessel.

Teflon Lining: The Guardian with Resistance

The reaction mixture is kept in a Teflon-lined (usually PTFE) chamber inside the autoclave. This chemically inert liner reduces contamination, resists harsh chemicals, and stops the autoclave’s metallic body from corroding. In addition to providing an additional degree of safety during high-pressure reactions, its non-stick surface facilitates homogenous nucleation and streamlines product recovery.

Safety Mandatory: Precautions for Autoclave Use

While autoclaves are powerful tools, they must be handled with care. Key safety precautions include

- Pre-Inspection: Always inspect the autoclave and Teflon liner for cracks, corrosion, or residue before use.

- Proper Sealing: Ensure the vessel is tightly sealed and all fittings are secure to prevent leaks under pressure.

- Controlled Heating: Use programmable temperature controllers to avoid overheating and pressure surges.

- Pressure Monitoring: Never exceed the rated pressure and temperature limits of the autoclave.

- Cooling Protocol: Allow the autoclave to cool naturally before opening. Rapid depressurization can be dangerous.

- Personal Protection: Always wear lab coats, gloves, and face shields when operating or opening the autoclave.

- Ventilation: Operate in a well-ventilated area or fume hood, especially when using volatile or toxic solvents.

No comment yet, add your voice below!