Automated Heat Treatment System for Large Metal Plates

Automated Heat Treatment System for Large Metal Plates

Engineered and Manufactured by Ants Innovations Pvt. Ltd., Maharashtra (in collaboration with CSIR–National Metallurgical Laboratory, Jamshedpur)

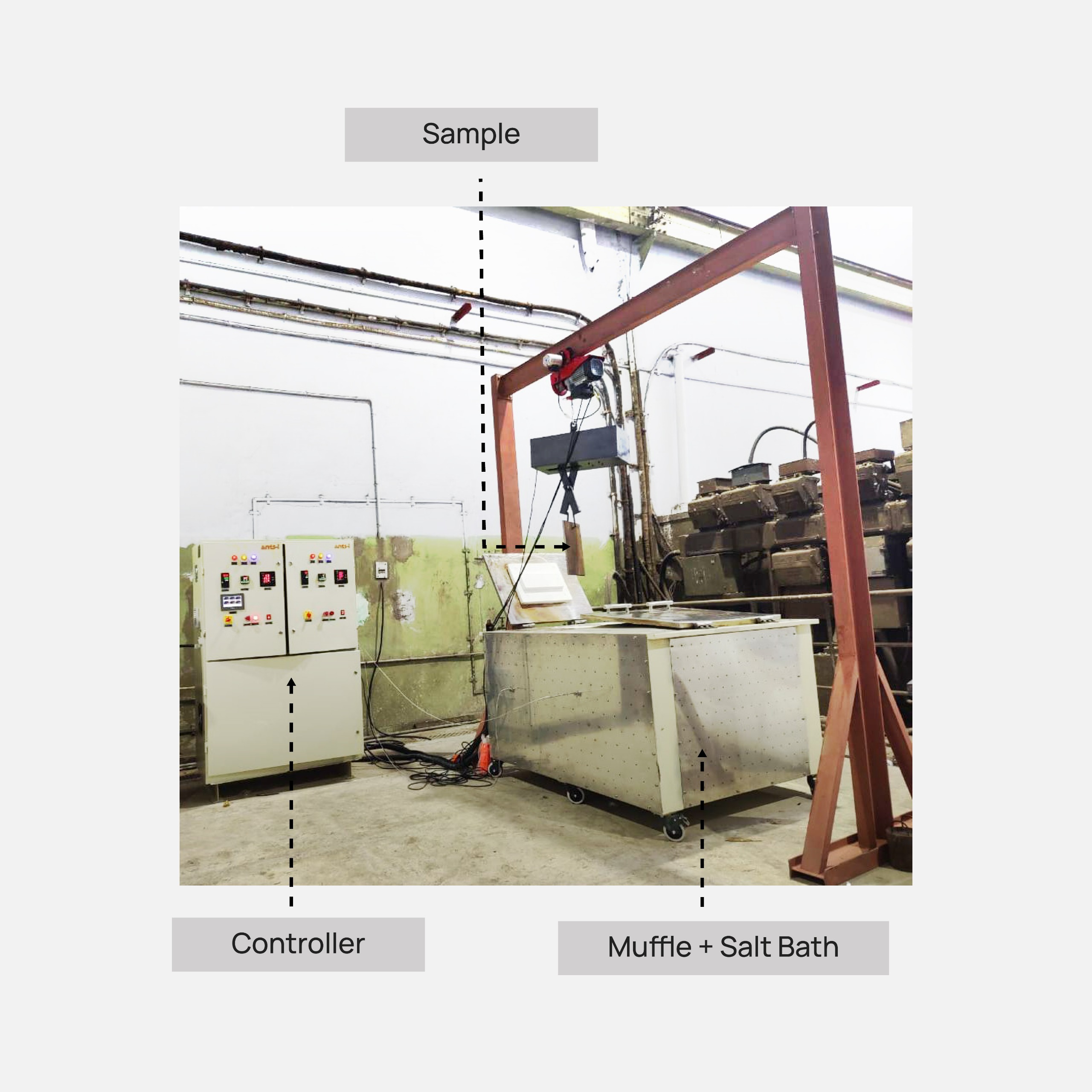

Ants Innovations proudly introduces a state-of-the-art Automated Heat Treatment System designed for high-precision thermal processing of large metal plates. Created to support advanced metallurgical research and pilot-scale production, this system combines intelligent automation, robust engineering, and precise thermal control to deliver unmatched reliability and performance.System Overview

This custom-built solution accommodates plates up to 300 mm × 450 mm × 70 mm, featuring a high-temperature muffle furnace and a controlled salt-bath quenching unit. The system ensures seamless, repeatable, and programmable heating–to–quenching transitions essential for developing and validating heat-treatment cycles.Key Capabilities

High-Temperature Muffle Furnace

Reaches 1100°C with excellent uniformity and controlled heating rates up to 20°C/min for consistent thermal profiles.

Precision Salt-Bath Quenching

A 70-litre salt pot enables rapid and uniform quenching within the 200–600°C zone, with cooling rates up to 5°C/min.

Fully Automated Material Handling

Motorised loading/unloading ensures safe, accurate, and time-critical transfer between furnace and quench bath: minimising variability and maximising repeatability.

Programmable Control Architecture

Intelligent control for heating, soaking, movement, and quenching cycles, enabling researchers and process engineers to design and execute highly repeatable experiments.

Ants Innovations: Thermal Systems Expertise and Innovative Solutions

Got A Project ?