Kickstarting Battery Recycling: A Thermal Perspective

With the surge in electric vehicles and portable electronics, the demand for lithium-ion battery recycling is growing rapidly. Startups entering this space face unique challenges, especially in selecting and integrating the right thermal process equipment to safely and efficiently recover valuable materials. This newsletter explores how thermal equipment manufacturers can support these emerging ventures.

Thermal Processing is Critical in Battery Recycling

Thermal processing is a foundational step in the battery recycling workflow, especially for lithium-ion batteries. It enables safe handling, efficient material recovery, and environmental compliance. Startups entering this space must understand the value of thermal technologies in transforming hazardous battery waste into reusable resources.

- Safe Deactivation and Pre-Treatment: Before any mechanical or chemical processing, batteries must be safely deactivated to prevent fire, explosion, or toxic gas release. Thermal pre-treatment systems, such as low-temperature ovens or controlled-atmosphere furnaces, are used to evaporate residual electrolytes and deactivate reactive components. This step is essential for worker safety and equipment protection.

- Pyrolysis and Binder Removal: Electrodes in lithium-ion batteries are bound with organic polymers like PVDF (polyvinylidene fluoride). Pyrolysis, conducted in oxygen-free environments at temperatures between 400–600°C, breaks down these binders and separates active materials from current collectors. This process produces a “black mass” rich in lithium, cobalt, nickel, and graphite: ready for further recovery.

- Calcination and Roasting for Material Recovery: Calcination is used to remove carbon residues and moisture from black mass, improving its purity and reactivity. Roasting, often performed in oxidizing atmospheres, converts metal compounds into oxides, making them more amenable to hydrometallurgical leaching. These thermal steps are crucial for maximizing recovery rates and ensuring downstream efficiency.

Equipment Requirements

Startups need scalable, modular, and cost-effective thermal systems. Manufacturers should focus on:

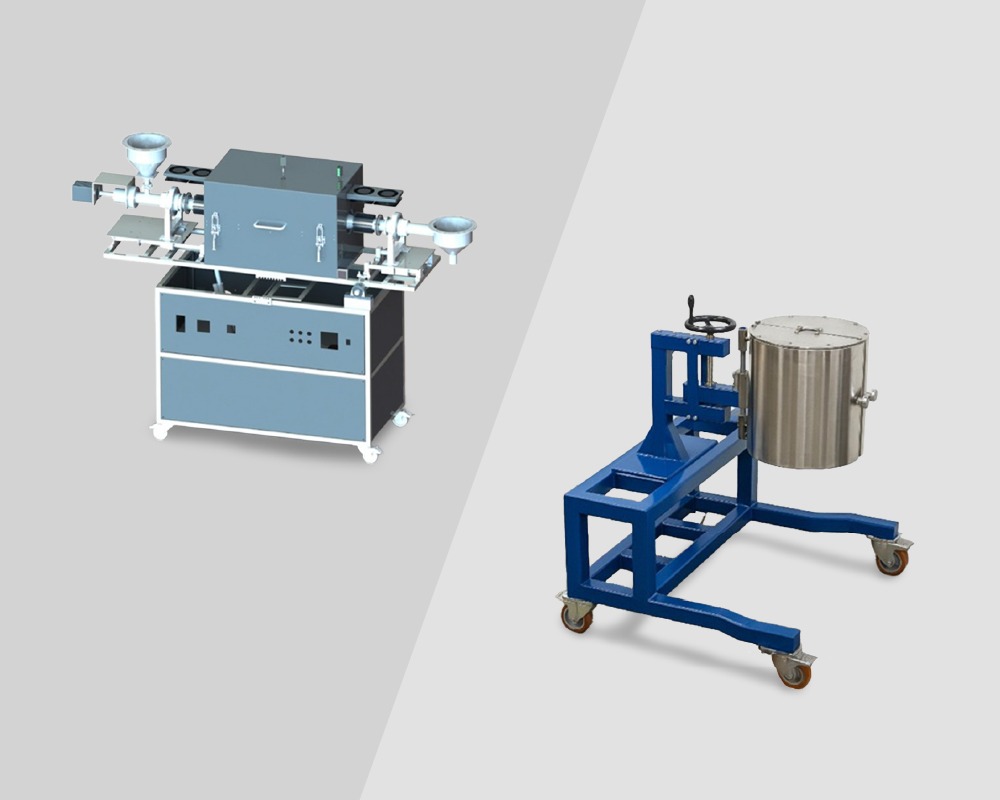

- Compact Rotary Kilns or Furnaces: Ideal for small-scale pyrolysis and calcination, with controlled atmospheres and temperature zones.

- Batch or Continuous Reactors: Suitable for flexible processing of varied battery chemistries.

- Off-Gas Treatment Systems: Crucial for capturing and neutralizing volatile organic compounds (VOCs) and fluorinated gases released during heating.

- Automation & Safety Controls: Integrated sensors, inert gas purging, and emergency shutdown systems to ensure safe operation.

Partnering for Success: Strategic Support

Startups in battery recycling often face steep technical and operational learning curves. Thermal process equipment manufacturers can play a pivotal role in accelerating their success by offering targeted support in three critical areas:

- Process Consultation: Early-stage companies benefit immensely from expert guidance on thermal reaction pathways, temperature profiles, and material handling strategies. By offering process consultation, manufacturers can help startups design safe, efficient workflows tailored to specific battery chemistries and recycling goals.

- Scale-Up & Pilot Line Setup: Transitioning from lab-scale experiments to pilot-scale operations is a major hurdle for startups. Equipment providers can assist by supplying modular systems for pyrolysis, calcination, and roasting, along with instrumentation for data collection and process optimization. This enables startups to validate their technology and prepare for commercial deployment.

- Custom System Design: Every recycling operation has unique feedstock, throughput, and environmental constraints. Manufacturers can offer custom-designed thermal systems such as rotary kilns, fluidized bed reactors, or batch furnaces engineered to meet specific performance, safety, and compliance requirements. Tailored solutions ensure scalability and long-term viability.

Battery recycling is not just a business opportunity; it’s a sustainability imperative. Thermal process equipment manufacturers are uniquely positioned to empower startups with the tools and expertise needed to build a cleaner, circular battery economy.

No comment yet, add your voice below!